Chuong trinh dao tao

Chuong trinh dao tao

Common Mistakes in Organic Waste Transformation: A Systems Efficiency Perspective

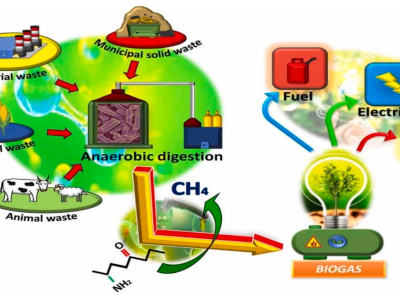

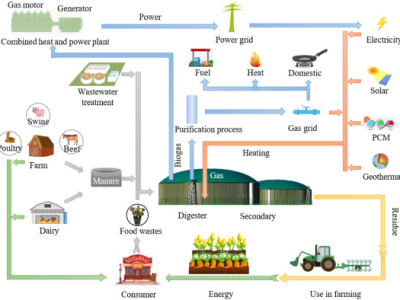

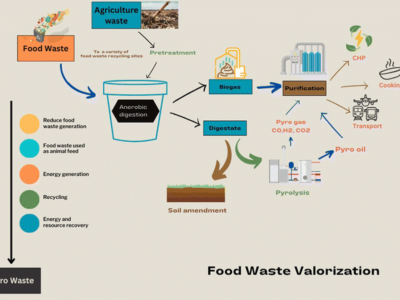

1. Misallocation of High-Value Organic Waste (Type 1) to Lower-Tier Pathways

In sustainable biomass utilization frameworks, Type 1 waste refers to nutrient-dense, putrescible organic materials suitable for direct transformation into animal feed via fermentation or heat-treatment. These include banana pseudostems, coffee pulp, peanut press cake, rice wine distillers’ byproducts, and similar agro-industrial residues.

A critical inefficiency occurs when such feed-grade substrates are diverted to insect-based bioconversion (e.g. Black Soldier Fly larvae) prematurely—without first exhausting their higher-value potential as livestock feed. Unless Type 1 waste is irreversibly spoiled or fermented beyond palatability, its use at Level 2 (insect farming) leads to substantial nutrient and protein loss. For example, BSF larvae exhibit a protein conversion efficiency of approximately 2:1, meaning that half the available protein in food waste is lost during larval biomass production.

Empirical field observations confirm that smallholders who directly feed food waste to pigs—and subsequently feed fresh pig manure to BSF larvae—can still recover ~66% of potential larval biomass compared to those who feed food waste directly to larvae. This two-stage system not only preserves more nutrients at the top of the food hierarchy, but also enhances nitrogen retention and system circularity.

2. Quantified Nutrient Loss in Larval Systems

In the study Bioconversion Efficiencies, Greenhouse Gas and Ammonia Emissions during Black Soldier Fly Rearing, larval systems showed:

- 38% nitrogen recovery

- 14% potassium recovery

- ~55% of feed energy remaining in residues

These figures point to major inefficiencies in nutrient utilization—particularly in contexts where alternative thermochemical or microbial processing of the same feedstock (e.g., fermentation) can yield directly consumable animal feeds with higher energy retention and lower transformation loss.

3. Case Studies on Superior Feed Value of Type 1 Inputs

Numerous peer-reviewed studies demonstrate the feed value of Type 1 inputs when processed via fermentation:

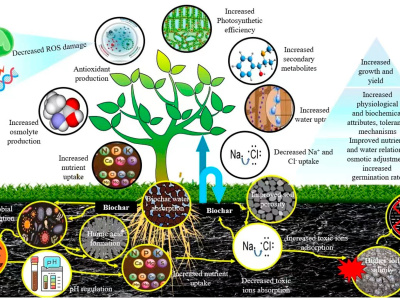

- Coffee pulp, spent brewery grain, and rice distillers’ byproducts have all been successfully incorporated into ruminant and monogastric diets with significant gains in animal productivity, feed conversion efficiency, and methane mitigation.

- In Laos, 4% inclusion (DM) of fermented brewery grain in a cassava foliage-based diet doubled goat growth rates. The addition of 0.84% biochar further improved weight gain by 26% and significantly lowered enteric methane emissions.

- In cattle, 5% supplementation with brewers’ grain increased nitrogen retention by ~50%; similarly, supplementation with rice wine byproduct led to a 60% improvement in live weight gain when biochar was added to the diet (Inthapanya et al., 2016).

- In native Moo Lath pigs, inclusion of 4% rice distillers’ byproduct improved feed conversion efficiency during pregnancy and lactation by 60%, with no performance loss when replacing soybean meal in growth diets.

These findings reinforce a core principle of circular agriculture: preserve feed-grade nutrients at the highest trophic level possible, and only downcycle material once their utility as direct feed has been exhausted.

4. Violations of Food System Efficiency: Food-to-Feed, Feed-to-Fuel Pathways

Modern food system sustainability frameworks emphasize minimizing trophic level cascades and caloric losses. Violating these principles results in systemic inefficiency:

- Feeding grains (e.g. soy, maize) to animals instead of directly to people results in only 17–30% caloric return to the human food chain. This translates into an estimated $1.32 trillion annual economic loss by 2050 (Stevenson, 2020).

- According to David Pimentel, the grain currently fed to U.S. livestock could feed 800 million people directly.

Worse still are cases where food-grade products like milk and eggs are used as fertilizer—a practice observed in parts of Vietnam. These actions represent a misallocation of high-energy-density inputs to low-efficiency outputs and contradict the foundational principles of resource cascading and food security.

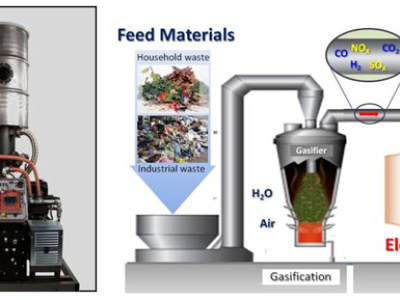

5. Unsustainable Biofuel Practices: A Cautionary Note

Fuel production from food crops (e.g., corn ethanol, palm oil biodiesel) is a fundamental misstep in climate and food policy. Data shows:

- Over 1/3 of U.S. corn is diverted to ethanol, despite studies confirming its higher carbon intensity than gasoline (PNAS, 2022).

- Palm and soybean oil biodiesel production emits 150–230g CO₂e/MJ, higher than most fossil fuels (Transport & Environment, 2021).

- George Monbiot calculates that 450 hectares are required for 1 MW biogas capacity from maize, versus 0.3 hectares for wind. Maize-related soil erosion further amplifies climate costs.

These practices exacerbate food insecurity and offer no net climate benefit. The global opportunity cost of biofuel production is estimated to displace food for 1.9 billion people.

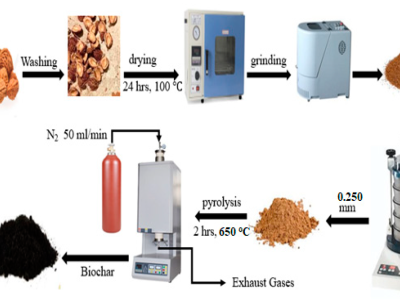

Instead, fuel production should prioritize Type 4 waste (low-grade biomass). Through syngas fermentation (e.g., Clostridium spp. conversion to ethanol), even cellulose and low-value organics can yield ethanol and biochar, bypassing food inputs entirely.

6. Sustainable Biofuel Options: From Waste, Not Food

While biodiesel from waste cooking oil (WCO) is more defensible, caution is warranted:

- Usable WCO may still serve as a medium for frying food waste.

- Rancid WCO can be separated using magnesium silicate filtration and processed via transesterification for biodiesel.

- Glycerol byproduct from WCO can be fermented into ethanol using Enterobacter aerogenes.

WCO-derived biodiesel exhibits:

- Higher cetane number

- Lower ash and carbon residue

- Improved engine performance and lower emissions

These benefits affirm WCO’s potential as a circular fuel, provided food-use separation is enforced and lifecycle emissions remain favorable.

Conclusion: Toward Trophic Efficiency and ESG-Aligned Waste Valorization

The hierarchy of organic waste utilization—Feed > Fertilizer > Fuel—should be strictly respected in ESG-driven agriculture and waste-to-value strategies. Missteps such as feeding food to insects, animals, or fuel systems violate principles of:

- Nutrient circularity

- Trophic efficiency

- Food system justice

- Climate-smart resource allocation

Future investments in bioresource management must prioritize high-value reuse, integrated bioconversion, and local fermentation solutions, especially in food-insecure and smallholder-dominated regions.

Author : Asean Farmers Team

![NGUYỄN ĐÌNH QUYỀN [VN]](https://aseanfarmers.com/wp-content/uploads/NGUYEN-DINH-QUYEN-VN-400x300.png)