Chuong trinh dao tao

Chuong trinh dao tao

High-Value Transformations of Chitosan, Fish, and Feather Waste

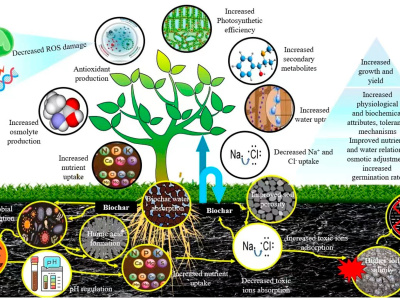

Chitosan: A Potent Antimicrobial and Functional Biomaterial

Select forms of chitosan have demonstrated powerful antibacterial, antiviral, insecticidal, and fungicidal activities:

- E. coli: Inhibited by shrimp-derived chitosan (Antibacterial activity of shrimp chitosan against Escherichia coli)

- Campylobacter spp.: Sensitive to chitosan’s antimicrobial action (Antimicrobial activity of chitosan against Campylobacter spp.)

- Salmonella Typhimurium: Significantly reduced on chicken skin surfaces when treated with chitosan (Effect of Chitosan as a Biological Sanitizer…)

- MRSA (Methicillin-Resistant Staphylococcus aureus): Targeted effectively by aminated and quaternized chitosan formulations (Antibacterial activity of aminoderivatized chitosans…)

Chitosan-based composites have also exhibited antiviral properties, including activity against H1N1 influenza A virus (Antiviral activity of silver nanoparticle/chitosan composites against H1N1…), and both chitosan and oligo-chitosan have demonstrated insecticidal and fungicidal potential, making them promising tools in sustainable agriculture (Insecticidal and Fungicidal Activities of Chitosan and Oligo-chitosan).

Iceland: A Model of Zero-Waste Fisheries

Iceland provides a striking example of resource optimization in the seafood industry. Historically, up to 60% of each cod was discarded as waste. Today, with advanced bioprocessing and value-chain innovation, that waste is transformed into premium health and cosmetic products.

While a cod fillet sells for approximately $12, the by-products—once discarded—can now be processed into goods worth up to $3,500 per fish (Icelanders Turn $12 Cod into $3,500 Worth of Products). This shift reflects a broader trend where industries extract maximum value from biomass once considered valueless. It demonstrates how intelligent reuse of by-products can:

- Create high-value product streams

- Reduce environmental pressure

- Promote job creation and sustainable development

Feather Waste: From Disposal Burden to Protein Goldmine

Globally, more than 10,000 tons of feather waste are generated every day, posing major disposal challenges due to the keratin-rich structure (90% keratin), which is highly resistant to natural degradation (AeroPowder).

However, biotechnological innovations have unlocked new possibilities:

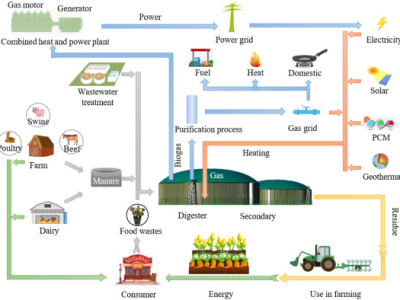

Feather Fermentation and Feed Protein

Using Bacillus licheniformis (strain PWD-1), feathers can be fermented into a protein-rich lysate, which, when supplemented with key amino acids, performs comparably to soybean meal in animal diets (Evaluation of a Bacterial Feather Fermentation Product…).

- The fermentation process not only eliminates waste but creates nutrient-dense, cost-effective protein suitable for livestock.

Dr. Jason Shih, Professor at North Carolina State University, has further shown that keratinase, the enzyme responsible for breaking down feathers, also degrades prions, due to similarities in protein structure (ENZYME FOUND TO DEGRADE PRIONS).

Industrial Applications of Keratinase

Keratin-degrading bacteria like Bacillus subtilis 1273 and fungi such as Aspergillus niger have proven effective at feather degradation. Beyond feed, keratinolytic enzymes have broad industrial uses in:

- Detergents and cosmetics

- Leather and textile processing

- Medical sterilization

- Biopesticides

- Prion deactivation (Keratinase Production by Bacillus spp… | Degradation of Feather Waste by Aspergillus niger)

Toward Human Food and Bioplastics

Scientists at Lund University (Sweden) have demonstrated the transformation of chicken feathers into edible human-grade protein:

- From 1 kg of feathers, 900 grams of digestible protein can be recovered.

- All the keratin protein is utilized, showing potential to replace fishmeal or soy in both human and animal diets (Wasted bird feathers turned into food).

In parallel, researchers are also exploring the use of feathers in bioplastics. Feathers can be combined with biodegradable polymers to create compostable materials suitable for packaging and industrial applications (Turning Chicken Feathers into Plastic | Chicken Feather Plastic?!).

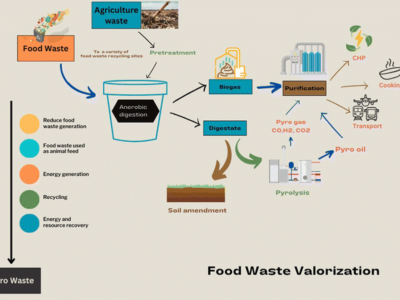

Conclusion: Waste Valorization as Circular Innovation

Whether it’s shrimp shells transformed into chitosan, cod by-products converted into cosmetics, or chicken feathers reimagined as food or plastic, these examples underscore the immense potential in what has traditionally been considered waste.

By embracing biotechnological fermentation, enzymatic processing, and product innovation, industries can:

- Eliminate pollution at the source

- Replace unsustainable materials

- Generate new revenue streams

- Support circular, zero-waste economies

Author : Asean Farmers Team

![NGUYỄN ĐÌNH QUYỀN [VN]](https://aseanfarmers.com/wp-content/uploads/NGUYEN-DINH-QUYEN-VN-400x300.png)