Chuong trinh dao tao

Chuong trinh dao tao

Transforming Food Waste with Superheated Steam: A Scalable Circular Solution

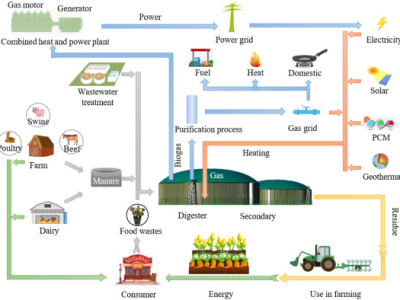

In food waste valorization, fermentation remains a core pathway, particularly when implemented on-farm. However, for broader urban-scale recycling, integrating superheated steam drying offers multiple advantages across food safety, nutrient retention, transport efficiency, and feed processing flexibility.

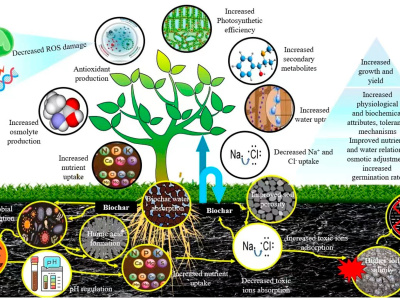

One key innovation is the use of biochar or rice hull filters to capture oil aerosols and cooking fumes generated during fry-cooking processes, enhancing air quality and adding value to the biofiltration medium.

Advantages of Superheated Steam Drying in Food Waste Processing

Drying food waste using superheated steam enables sterilization without denaturing proteins or degrading essential vitamins and nutrients. Once dried, food waste can be:

- Ground into a stable powder

- Blended with biochar powder to enhance nutritional and digestive properties

- Pelletized for easy storage, transport, and controlled formulation

These lightweight, nutrient-rich pellets offer several benefits:

- Eliminate over 80% of the weight and volume of raw food waste

- Require no refrigeration

- Can be customized for poultry, swine, ruminants, fish, and crustaceans

- Compete with commercial feeds costing $400–$1,000/ton

Moisture content in fermentation processes can also be precisely controlled by adding water to powdered food waste, offering greater consistency and safety in feed preparation.

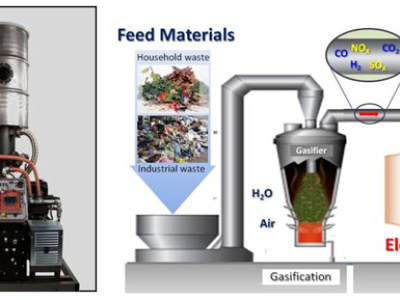

Low-Cost Superheated Steam Technology

A basic superheated steam generator (e.g., 150 Gasifier Superheated Steam Unit) can be fabricated for as little as $130 USD. The unit operates by channeling saturated steam—produced in a pressure cooker—between the reactor core and the housing of a gasifier, where it absorbs residual heat to become superheated. Alternatively, the steam can be routed across a heat transfer disc to achieve the same effect.

Urban Decentralization and Social Enterprise Opportunities

This technology supports a decentralized urban circular model:

- Restaurants could dry food waste on-site and store food waste powder for weekly or monthly collection

- Households could supply food waste to localized processing stations

- Food waste collectors could be organized into social enterprises, generating revenue from pellet sales

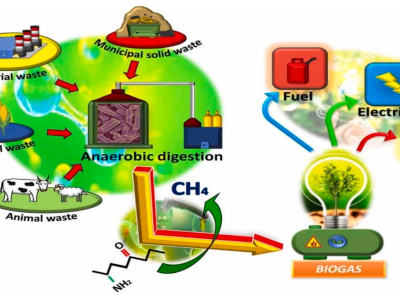

Municipalities could eliminate the need for food waste landfilling, incineration, composting, or biodigestion, significantly reducing costs and environmental impacts. Moreover, superheated steam dryers are applicable beyond food waste—for example, drying fruit peels, coffee pulp, or other agro-industrial by-products.

Biochar + Food Waste Pellets: A Circular Revenue Engine

A key synergy lies in pairing food waste powder with biochar:

- Restaurants receive free fuel pellets in exchange for the biochar they produce onsite

- High-grade biochar in Vietnam sells for over $2,120/ton, while pellet production costs are as low as $50/ton

- Gasifier fuel pellets can be made entirely from agricultural residues and forestry by-products, avoiding deforestation

Vietnam alone produces 8.8 million tons of rice hulls annually, most of which is currently discarded or burned. When gasified, one ton of rice hull pellets yields 330 kg of biochar—worth over $700 USD, more than 14 times the cost of the pellets. This creates a profitable, low-emission alternative to traditional biochar kilns.

A Scalable, Inclusive Model for Global Cities

This system can be replicated in every major city worldwide:

- Restaurants benefit from free fuel and free waste collection

- Social enterprises generate income from processing and selling pellets

- Municipalities save on landfill and incineration costs

- Households receive clean cooking fuel in exchange for waste and biochar

By aligning decentralized waste valorization, clean energy, and regenerative agriculture, this model demonstrates how food waste can become a keystone in local circular economies, delivering environmental, social, and economic returns.

Author : Asean Farmers Team

![NGUYỄN ĐÌNH QUYỀN [VN]](https://aseanfarmers.com/wp-content/uploads/NGUYEN-DINH-QUYEN-VN-400x300.png)