Chuong trinh dao tao

Chuong trinh dao tao

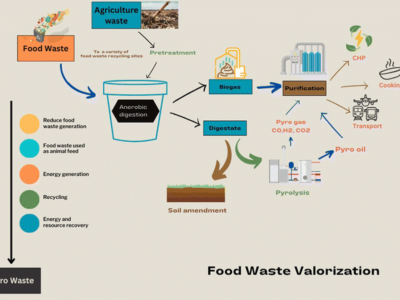

Turning Food Waste into Profitable Feed and Clean Energy: A Decentralized, Circular Solution for Cities and Small Farms

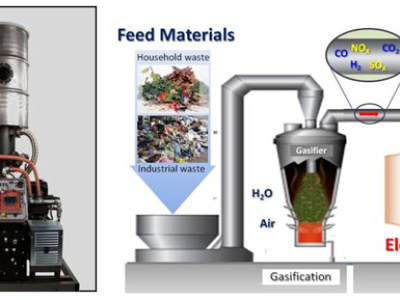

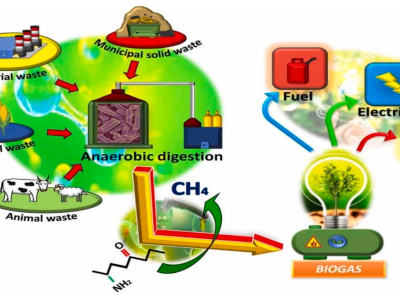

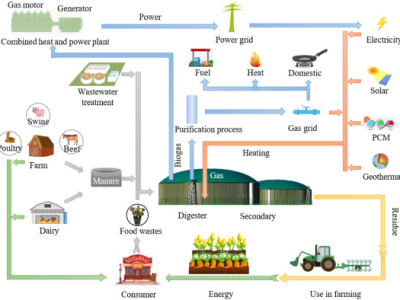

Food waste is not just an environmental burden—it is a vast, untapped resource that can be transformed into high-value products such as animal feed and biochar when processed with low-cost thermal technologies. Small farmers, urban restaurants, and decentralized waste processors can all participate in a profitable and ecologically regenerative system by integrating gasification, fry-cooking, and superheated steam drying.

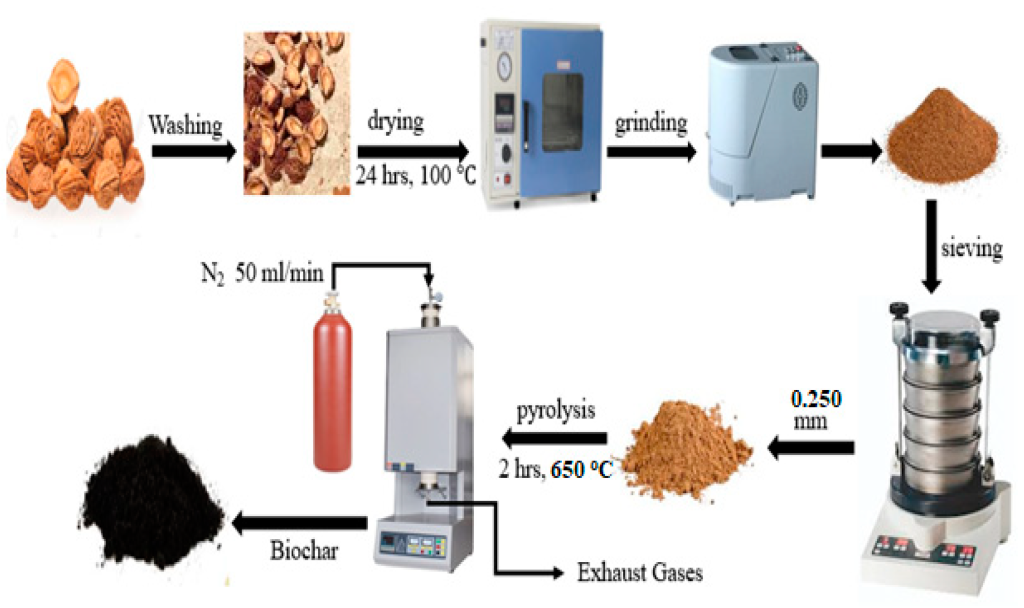

1. Fry-Cooking and Biochar Production: Two Outputs, One Simple Process

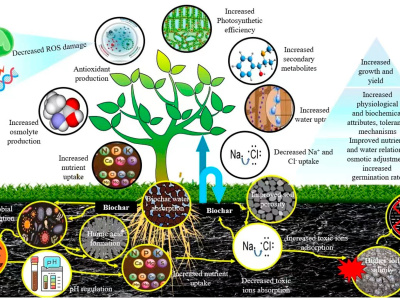

Fry-cooking food waste using inexpensive batch gasifiers offers an elegant, low-tech solution with multiple benefits. Batch gasifiers—costing less than conventional burners—can operate for 3 to 10 hours per cycle. The process not only cooks the waste, making it safe and digestible, but also produces high-value biochar as a byproduct. In contrast to polluting traditional biochar kilns, this system captures and utilizes heat efficiently. In fact, the thermal energy required for cooking is effectively paid for by the value of the biochar produced.

Fry-cooked food waste can be vacuum-sealed and pelletized, extending its shelf life and enabling easy transportation to farms. Once there, it can be fermented or directly used as livestock feed. Meanwhile, cooking fumes are captured in affordable and eco-friendly filters made from rice hulls or biochar itself—an example of closed-loop, environmentally sound engineering.

2. Superheated Steam Drying: Preserving Nutrients and Reducing Waste Volume

Another advanced yet accessible method involves using superheated steam to dry food waste. This technique sterilizes the waste without denaturing proteins or degrading essential vitamins, preserving its nutritional value. Once dried, food waste becomes easy to grind into a fine powder, significantly reducing its weight and volume—by over 80%—and cutting transport costs drastically.

This powdered food waste can be:

- Mixed with biochar to create high-quality feed pellets

- Custom-blended to meet the specific dietary needs of poultry, livestock, aquaculture, or crustaceans

- Combined with other biomass or co-products

- Fermented with precision moisture control

Small-scale superheated steam generators, such as the 150 Gasifier Superheated Steam Unit, can be built for as little as $130 USD. These systems reroute saturated steam from a pressure cooker into the gasifier’s outer chamber, using waste heat to produce superheated steam—a simple but powerful innovation.

3. A Model for Cities, Restaurants, and Households

Urban implementation of this technology is highly feasible. Restaurants can install compact superheated steam dryers, store food waste powder on-site, and schedule weekly or monthly pickups. Households can set aside food waste for local collection hubs. A network of decentralized fry-cooking or drying stations can be established across cities, operated by social enterprises or cooperatives. These processors could generate significant income from selling biochar and feed pellets—eliminating the need for municipal landfilling, incineration, composting, or biodigestion.

4. Economic Potential and Environmental Benefits

Pelletized food waste, once dried, can be stored without refrigeration and replaces imported commercial feed priced between $400 and $1,000 per ton. In Vietnam, high-grade biochar sells for approximately $2,120 per ton, while producing one ton of fuel pellets from agricultural waste costs only about $50 USD. Since fuel pellets can be made from rice husks, sawdust, and other non-timber residues, no tree felling is required.

Vietnam, for example, generates over 8.8 million tons of rice husks annually, much of which is burned or dumped. Gasifying one ton of rice husk pellets yields about 330 kg of biochar—worth over $700 USD. This equates to clean, high-grade heat generation with profit, eliminating the need for traditional, polluting kilns.

Restaurants could receive free pellet fuel in exchange for returning the biochar they produce, while also benefiting from free food waste removal. Similarly, households could receive the same advantages. The system yields two high-value commodities—feed pellets and biochar—while dramatically reducing the environmental and financial burden on local governments.

5. Advancing Waste Hierarchies: From Composting to Direct Feed Use

In Vietnam, an estimated 70% of household waste is food waste, and the remaining portion consists mainly of recyclable materials. When food waste is separated and fry-cooked or dried, recyclables become cleaner, more accessible, and of higher value. This upstream separation dramatically enhances waste management efficiency.

Moreover, processing food waste into direct animal feed (Level 1 reuse) is more efficient than feeding it to black soldier fly larvae or worms (Level 2), as it eliminates one trophic level and maximizes nutrient return to agriculture. Even if food waste is spoiled and unsuitable for drying, it can still be directed to insect larvae. In either case, composting food waste (Level 3) becomes less attractive due to lower nutrient recovery efficiency and higher management cost.

Conclusion: A Profitable, Scalable Model for Circular Agriculture

By integrating fry-cooking, gasification, and steam drying, a decentralized and circular model of food waste recycling can be implemented—one that is scalable, economically viable, and environmentally sound. Small farms and urban centers alike can participate in this system, transforming food waste into nutrient-rich feed and valuable biochar, while avoiding landfilling, emissions, and the waste of biomass. This model not only aligns with regenerative agricultural principles but also offers a compelling pathway for sustainable urban-rural integration.

Author : Asean Farmers Expert Team

![NGUYỄN ĐÌNH QUYỀN [VN]](https://aseanfarmers.com/wp-content/uploads/NGUYEN-DINH-QUYEN-VN-400x300.png)